Cogent TYPE‑C™ Column End‑Fitting Hardware, Dimensions & Best‑Practice Connections

Selecting and installing the correct end‑fitting hardware is critical to preserving efficiency and minimizing extra‑column band broadening in HPLC.

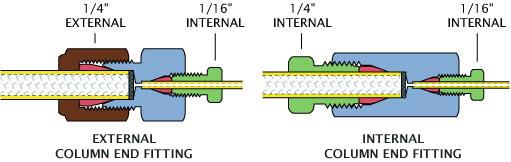

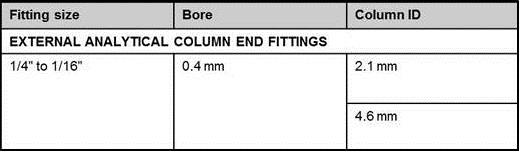

Cogent TYPE‑C™ analytical columns and guard holders use industry‑standard Valco® sealing depths, with Type 316 stainless‑steel end fittings and a 0.4 mm bore on analytical formats. These specifications ensure broad instrument compatibility and robust, leak‑free operation when connections are assembled correctly.

End‑Fitting & Material Specifications (Analytical Columns)

- Sealing depth: Valco® standard (industry standard) for reliable, reproducible seating across systems.

- End‑fitting bore: 0.4 mm for analytical columns, balancing low dead‑volume with mechanical robustness.

- Material: Type 316 stainless steel to provide corrosion resistance and pressure stability typical of modern LC systems.

Recommended Connectors: Direct Adaptive Di‑Ad™ Column Connectors

For routine column installation and column‑to‑guard or column‑to‑column coupling, Cogent recommends Direct Adaptive Di‑Ad™ connectors. Unlike ferrule‑based fittings that permanently swage onto tubing, Di‑Ad™ connectors do not lock to a single pilot depth, helping prevent dead‑volume traps and allowing you to make repeatable, zero‑gap connections every time.

Why Di‑Ad™ helps method integrity

- No permanent swage → the same piece of tubing can be reseated without changing cut length.

- Adaptive pilot depth → minimizes the risk of creating a mixing chamber at the joint.

- Consistent low dead‑volume at critical interfaces (injector ↔ column; column ↔ detector).

Tip: If you need a compact, color‑coded way to put columns in series or attach guards, MICROSOLV’s column couplers provide universal fit for 10‑32 ports and keep through‑holes matched to tubing IDs to protect efficiency.

Seating Depth: The #1 Cause of Connection‑Induced Problems

When using traditional ferrule fittings, reusing a pre‑swaged tube on a different port can misalign the tube’s pilot depth relative to the new connector. This is a common root cause of leaks, micro‑mixing, and accidental frit/tube damage.

- Too deep: the fitting may fail to seal; tightening can damage the tubing end.

- Too shallow: the tubing tip doesn’t meet the end‑fitting seat, leaving a mixing chamber (dead volume) that broadens peaks and distorts early‑eluters.

Because these critical connections govern band dispersion, always verify proper pilot depth at the injector‑to‑column and column‑to‑detector interfaces.

Installation Pitfalls & How to Avoid Them

- Over‑ or under‑tightening finger‑tight or standard fittings can create leaks or gaps. Tighten to the manufacturer’s guidance; avoid “just a bit more” turns after first resistance.

- Re‑using swaged tubing on a different brand/port risks depth mismatch. If you must reuse, re‑cut the end square, deburr, and reset ferrules for the new port—better yet, use Di‑Ad™.

- Guard systems: match the stationary phase and ID to your analytical column so protection does not alter selectivity; use the correct guard holder to maintain low‑dead‑volume geometry.

Quick Checklist for Low‑Dispersion Connections

-

Confirm end‑fittings: Valco® seating depth; analytical bore 0.4 mm; 316 SS.

-

Prefer Di‑Ad™ connectors to avoid permanent swaging and pilot‑depth errors.

-

If ferrules are used, re‑cut/deburr tubing and set ferrules fresh for each new port.

-

Inspect for leaks at injector↔column and column↔detector after first pressurization.

-

Guard correctly: match phase/ID and install with the recommended holder.

Click HERE for ordering information and pictures of the Di-Ad™ column connectors.